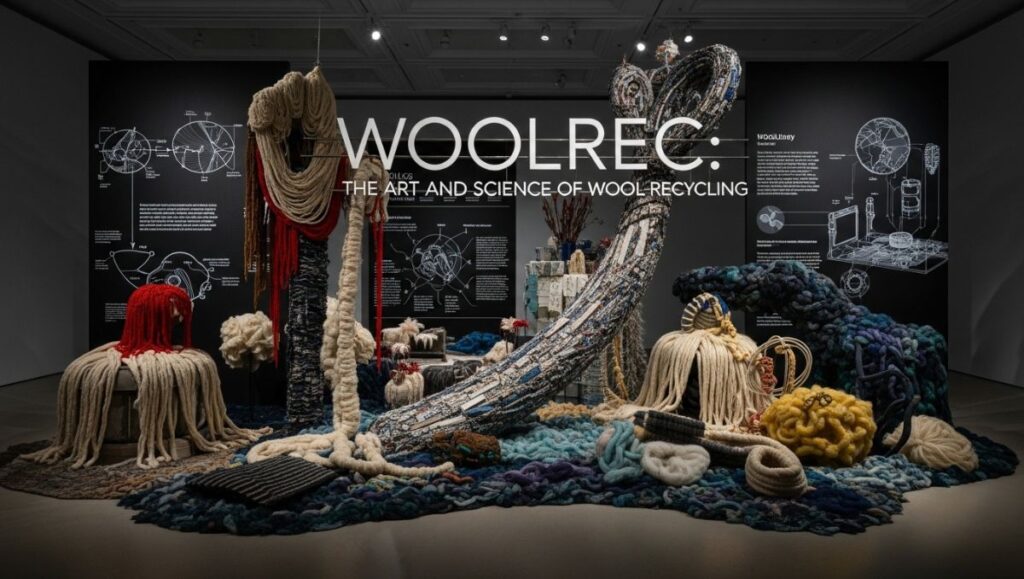

In a world where sustainability has become more than just a trend, the textile industry faces growing pressure to reinvent its production and consumption models. Wool, a natural fiber prized for its warmth, softness, and durability, stands out as a material perfectly suited for circular design. Woolrec, short for wool recycling, represents a modern response to fast fashion’s waste problem — combining traditional craftsmanship with innovative recycling technologies to extend the life of wool garments and reduce environmental impact.

Wool recycling isn’t new. Historically, communities across Europe reused old wool to make blankets and industrial fabrics. But in recent decades, this practice has gained new relevance as part of the global shift toward a sustainable textile economy. Today, Woolrec encompasses both mechanical and chemical recycling processes that transform used wool into valuable raw materials for new products.

The Importance of Wool Recycling

1. Addressing Textile Waste

The fashion industry produces over 90 million tons of textile waste annually, and only a small fraction is recycled. Wool represents a high-value material that should not end up in landfills. Through Woolrec processes, discarded wool clothing and scraps can be recovered, sorted, and transformed into fibers ready for reuse — minimizing waste and promoting a circular economy.

2. Reducing Environmental Impact

Wool is biodegradable, but that doesn’t mean it’s harmless when wasted. Producing virgin wool requires land, water, and energy, and raising sheep generates methane emissions. By recycling wool, we reduce demand for new raw materials and cut greenhouse gas emissions associated with production. Woolrec thus supports key sustainability goals, such as lower carbon footprints and responsible resource use.

3. Preserving Natural Resources

Each kilogram of recycled wool saves liters of water and reduces the need for new animal fiber production. This conservation of natural resources directly contributes to a more resilient and sustainable textile supply chain. Furthermore, Woolrec helps preserve the craftsmanship and traditional skills associated with wool processing, ensuring cultural and industrial continuity.

How Woolrec Works: The Recycling Process

1. Collection and Sorting

The Woolrec process begins with the collection of post-consumer wool garments and pre-consumer textile waste. Specialized facilities sort the materials by fiber type, color, and quality. Sorting is critical — pure wool garments are ideal for recycling, while wool blends require more advanced separation techniques. In some cases, automated systems use optical scanners or AI-based tools to classify textiles accurately.

2. Cleaning and Preparation

Before recycling, the wool must be cleaned to remove impurities such as dirt, oil, and synthetic residues. This process, known as scouring, uses eco-friendly detergents and minimal water to preserve fiber integrity. Once cleaned, the textiles are mechanically shredded into smaller pieces to prepare them for fiber recovery.

3. Mechanical Recycling

Mechanical recycling is the most common Woolrec method. The shredded fabric passes through a series of machines that pull and tease the fibers apart, turning them into a fluffy wool blend known as shoddy. This recycled fiber can then be spun into yarns for new textiles. While mechanically recycled wool is slightly shorter in fiber length than virgin wool, it remains highly valuable for products like coats, blankets, and upholstery.

4. Chemical Recycling

A newer, more advanced approach to Woolrec involves chemical recycling. This process dissolves the wool in environmentally safe solvents to separate pure keratin protein fibers. The resulting solution can be regenerated into high-quality wool-like fibers. Though still in development, chemical recycling holds immense potential for creating closed-loop systems that recover wool at molecular levels, maintaining fiber strength and quality.

5. Re-Spinning and Fabric Production

After recovery, recycled wool fibers are blended with virgin fibers (if necessary) to enhance durability and texture. The blend is then spun into yarns, woven or knitted into fabrics, and transformed into new garments. Many fashion brands now proudly highlight “Recycled Wool” or “Woolrec” labels to communicate their commitment to circular production.

Applications of Recycled Wool

1. Fashion Industry

The most visible use of Woolrec materials is in fashion. Brands are increasingly integrating recycled wool into coats, scarves, and sweaters. Because of its natural insulation properties, recycled wool provides both comfort and sustainability. High-end designers, including Stella McCartney and Patagonia, have embraced recycled wool to reduce reliance on virgin materials.

2. Interior and Home Textiles

Recycled wool finds applications beyond clothing. Its warmth and durability make it ideal for home furnishings such as rugs, cushions, and blankets. The soft yet sturdy nature of recycled wool provides both aesthetic appeal and long-lasting performance, aligning with eco-conscious interior design trends.

3. Industrial Uses

Lower-grade recycled wool is used in industrial applications, such as insulation materials, soundproofing panels, and automotive linings. These applications showcase the versatility of Woolrec, proving that even fibers too short for garments can still contribute to sustainability in other industries.

The Economic Benefits of Woolrec

1. Cost Efficiency

Recycling wool can be more cost-effective than producing new fibers, especially when energy and raw material prices rise. By reusing existing resources, manufacturers lower production costs while meeting consumer demand for sustainable products.

2. Job Creation and Local Economies

Wool recycling facilities generate employment in sorting, processing, and quality control. Regions with strong wool traditions, such as Yorkshire in the UK or Prato in Italy, have revived local economies through Woolrec initiatives. This synergy between tradition and innovation fosters economic resilience and community pride.

3. Brand Value and Consumer Trust

Companies that adopt Woolrec practices strengthen their brand reputation. Modern consumers increasingly favor eco-friendly brands, and transparency about recycled content enhances credibility. By adopting Woolrec materials, brands not only meet sustainability targets but also attract ethically minded customers.

Challenges Facing Woolrec

1. Quality Degradation

Mechanical recycling can shorten fibers, affecting yarn strength and texture. This limitation often requires blending recycled wool with virgin wool to achieve the desired quality. Research continues to improve fiber recovery techniques and maintain product integrity.

2. Sorting Complexity

Sorting wool garments remains labor-intensive. Mixed fiber compositions — such as wool blended with polyester or acrylic — complicate recycling. Advances in AI-driven sorting and fiber identification are helping overcome this issue but remain costly for smaller recyclers.

3. Limited Consumer Awareness

Despite its environmental benefits, many consumers are unaware of Woolrec. Misconceptions about quality and comfort persist. Educational campaigns and clear labeling can help bridge this gap, encouraging consumers to value recycled wool products.

Innovations Driving the Future of Woolrec

1. Digital Traceability

Blockchain and digital tagging systems now allow full traceability of recycled wool fibers from collection to finished product. This transparency builds trust and verifies sustainability claims, making Woolrec part of the broader ethical fashion movement.

2. Smart Recycling Technologies

New machinery integrates sensors and automation to optimize the recycling process, reducing contamination and energy use. Advanced fiber identification systems can separate wool from synthetics with precision, ensuring higher recycling yields.

3. Circular Design Integration

Designers are beginning to create garments specifically intended for recycling — using single fibers, easy-to-remove trims, and recyclable dyes. This shift toward “design for disassembly” ensures future Woolrec cycles are even more efficient and sustainable.

The Role of Consumers in Woolrec

1. Choosing Wisely

Consumers play a crucial role in promoting wool recycling. By purchasing garments labeled as recycled or recyclable wool, individuals support circular production models. Choosing timeless, durable pieces over fast fashion also reduces textile waste.

2. Responsible Disposal

Instead of discarding old wool garments, consumers can donate, resell, or return them through take-back programs. Many brands now offer recycling drop-off points or incentives for returning used items — directly feeding materials into the Woolrec cycle.

3. Educating and Advocating

Public awareness is essential. When consumers understand that Woolrec products offer the same warmth, comfort, and beauty as virgin wool — with far less environmental cost — demand will naturally increase, driving systemic change in the industry.

Conclusion

Woolrec stands as a symbol of responsible innovation in the textile industry. It embodies the balance between nature and technology, honoring wool’s traditional value while embracing modern recycling techniques. As sustainability becomes central to textile manufacturing, the concept of Woolrec reminds us that every fiber has a second life waiting to be woven.

By reimagining waste as a resource, Woolrec not only conserves materials but also revives local craftsmanship, reduces environmental harm, and inspires a new generation of circular designers. The future of fashion depends on such initiatives — ones that close the loop, one recycled thread at a time.